Heat shrinkers

Machinery for packaging palletized products

Ring heat shrinker

The FG120 heat shrink oven is the latest technological frontier in the packaging field as it allows high productivity with low consumption. It has four latest generation gas burners emitting hot blown air, which guarantee high production versatility, perfect and uniform heat shrinkage of the product (with heat shrink film) safeguarding it from bad weather and infiltrations. To ensure greater stability to the product, it is possible to insert a pallet lifting device combined with a suction system, to anchor the film in the lower part of the pallet. Possibility of insertion into already productive lines.

GAS rotary table heat shrinker

The gas rotary table heat shrinker mod. T100 it is suitable for the packaging of palletised products of any nature and shape, using heat-shrink film. It is equipped with all the systems to work safely, as required by the regulations currently in force.

During the heat shrinking of the pallet, the rotation speed of the pallet will be varied as the edges pass to allow the heat shrinking of the film to be optimized and to guarantee that the product is aesthetically pleasing.

Electric rotary table heat shrinker

The mobile heat shrink mod. T110 is suitable for the packaging of palletised products of any nature and shape, using heat-shrink film. It can also be used indoors and is easily transportable. Furthermore, it is possible to customize the heat shrinking process by acting on some parameters, thus adapting to the characteristics of the product to be packaged and the type of film used. Thanks to an automatic control system, the burner approaches the pallet while maintaining a constant distance from the pallet, whatever its shape: in this way optimal retraction is obtained, guaranteeing high speed and quality. The operator can choose to shrink some areas of the pallet more than others, making simple adjustments from the machine's display, equipped with the controls necessary for this type of operation.

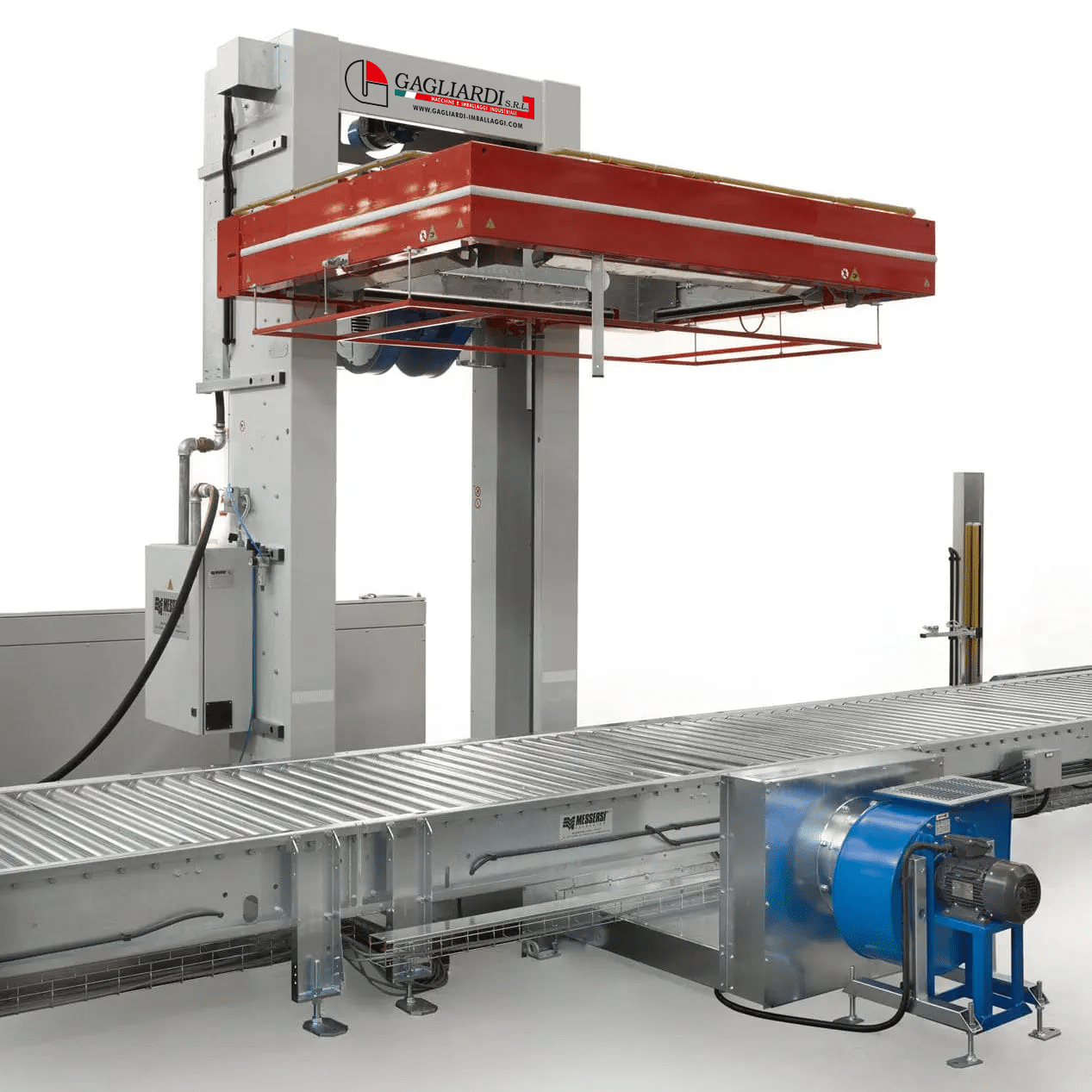

Combined hooding machine

The SH51 combined hooding machine hoods products palletised with tubular heat-shrink film. A single system for the best solution for the preparation, opening and positioning of hoods made from tubulars with side gussets together with quality heat shrinkage via an innovative ring hot air generator. The machine combines and synchronizes three distinct and independent phases (preparation of the tubular - transshipment of the tubular - hooding and heat shrinking) organizing them into a single process which minimizes the downtime of the different devices guaranteeing exceptional levels of productivity (up to 140 packs/hour) . The tubular gripping and manipulation system is structurally independent from the heat-shrinking system: this allows the heat-shrinking arc not to interfere with the gripping arc, guaranteeing maximum reliability in terms of wear of the components and wiring.

Consult the vast range of Gagliardi Imballaggi heat-shrink caps and films on reels that can be combined with these machines

Gagliardi Packaging

Heat shrinkers Gagliardi Imballaggi Srl

Among the vast choice of packaging machinery, the company Gagliardi Srl sells heat shrinkers. The heat shrinkers offered by the company are suitable for the packaging of palletised products of any nature and shape through the use of heat shrink film. The need to guarantee load stability, facilitate warehouse storage and safety during transport make the heat shrinker a rotary table is the indispensable tool for correct product handling.

- The heat shrinkers offered by Gagliardi Srl are produced by Messersì Packaging, a leading Italian company in the sector.